1.1.3 Strategy

The Viscofan Group has a business model with a technological and geographical proposal that is unique in the market, based on the solid shared values of a team, aimed at creating value in a sustainable manner for all our stakeholders. As a result of this model, Viscofan is a leader in the casing market and offers growth propositions in the food and health sectors outside the traditional business.

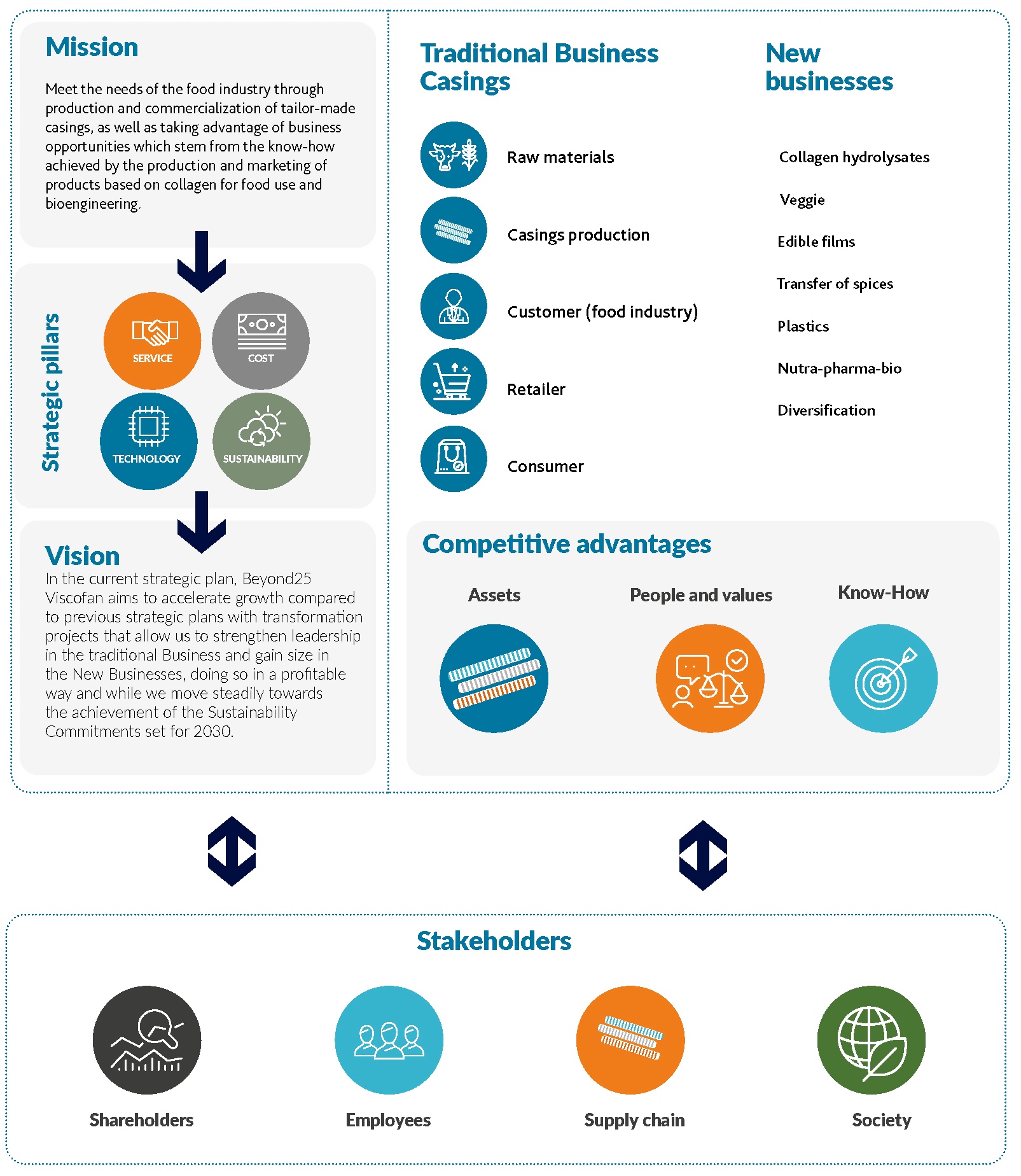

Our business model outline:

Strategy, business model and value chain

ESRS 2 SBM-1

Our purpose and mission

Purpose

From 2022, Viscofan has a new purpose with which it wants to go beyond traditional boundaries "Reshaping food and wellbeing. For many, for long", seeking to help to provide access to food and nutrition throughout the world, and to improve the well-being and health of people.

"Reshaping food and wellbeing" means that: our technology and our global presence enables us to be in a condition to forge a better world. We contribute to improve access to food throughout the world and we can also help, through nutrition and our knowledge, the well-being of human beings.

“For many” means that: if something characterises us, it is that we have always wanted to be important, to generate an impact; hence, our scope of action in the world is, “for many” - the more people that can enjoy our products, services or solutions, the better it is for our purpose.

“For long” means that: we generate an impact that remains, a future project, a project that intends to be forever, “for a long time”. It is an impact for everyone, for life, for the well-being of everybody. It is our sustainable proposal.

Mission

Meet food industry needs through the production and sale of artificial casings, and to seize the business opportunities that arise from know-how achieved by the company through the production and sales of collagen-based products for food use.

Beyond25 Strategy

The current strategic plan, called Beyond25, maintains the ambition to transform the Company in the same way as in the previous strategic plans. To this end, Viscofan expanded its business scope with a new purpose "Reshaping food and wellbeing. For many, for long”.

This means redefining our business model with a new approach to the market that combines our strong competitive advantages: the combination of the world's largest geographical presence, both productive and commercial, with a wide and unique catalogue of products, developed on the basis of its own technology and know-how, which continue to develop continuously thanks to a culture of excellence and continuous improvement, based on solid values and ethical principles shared by a highly committed team.

This strategic plan has four leading management regions to have greater market proximity and flexibility: Europe, Middle East and Africa (EMEA), North America (NAM), Asia Pacific (APAC) and South America (SAM), completed with a cross-cutting "New Business" division.

In addition, the strategy is based on an approach to the market that distinguishes between the Traditional Business (which includes cellulosic, collagen and fibrous) where Viscofan is in a privileged position to continue to take advantage of growth opportunities; and the New Business (which includes tubular plastics, packaging and third parties, edible casings, functional solutions, nutra-medical-pharma products, as well as diversification activities), where Viscofan wants to leverage its know-how as a catalyst for innovation to expand into new markets with attractive growth trends in the food, wellness and health sectors.

The strategy is based on four cross-cutting pillars: service, cost, technology and sustainability, with the ambition to lead the market in each of these areas.

Also, to drive change, the Digitalisation and People lever has been introduced, with people management and digital transformation initiatives to help streamline processes, boost career development and improve work-life balance.

In accordance with this strategic plan, Viscofan has its 2022-2025 Sustainability Action Plan with specific projects to combat climate change, measures to reduce water consumption and improvements to transform our processes into a more circular economy and reinforce our commitments to the Sustainable Development Goals of the United Nations 2030 Agenda.

Viscofan now has six essential commitments to our sustainability. Of these, although without setting a specific goal, it has two in which we can make a contribution through our products and services:

SDG 2. Zero hunger: belonging to the food market carries with it a great responsibility: that of providing millions of people worldwide with access to basic nutrition. As a global leader in artificial casings, the Viscofan Group contributes to the development of products that help to avoid food waste and it invests in R&D&i that enables more efficient and sustainable processes to manufacture cold meats. It also seeks to work with NGOs whose business nucleus is based on reducing hunger and to develop specific products that combat malnutrition.

SDG 3. Good health and well-being. Viscofan undertakes to transform the ample knowledge developed in the processing, use and transformation of raw materials, especially collagen, in products and solutions that contribute to improve the health and well-being of people. Collagen is the most abundant protein of the human body and of animals but, in turn, it is a singular versatile material and, therefore, is used in various areas that are beneficial for people, such as regenerative medicine, nutrition, health and life sciences.

For their part, the main strategic projects carried out in the 2024 financial year are detailed below:

- Construction and commissioning of a cellulosic and collagen casing converting plant in Rayong, Thailand.

- Acquisition of a 60% stake in the companies Brasfibra and Master Couros in Brazil, promoting collagen applications within the New Business division.

- Progress in investments and projects for the decarbonisation and diversification of energy sources at the Cáseda plant in Spain (biomass, electric boilers, solar park, green hydrogen).

- Implementation and approval by the Board of Directors of a Net Zero Plan for the Viscofan Group.

In addition, the strategy, the resilience of the business model and the specific action measures have been detailed in each ESRS.

Our markets

With the Beyond25 strategic plan, commercial and operational strategies have been reoriented, distinguishing between the sales of what has been called Traditional

Business, which includes casings based on collagen, cellulosic and fibrous technology, and sales of New Business, which includes plastic casings and the rest of the products and services. These two divisions are not identified within the categories of the sectors of the ESRS, so they are considered as "Other".

In addition, to a lesser extent, 5% of the Group's revenue comes from energy sales. They include the cogeneration activity, which in the Viscofan Group consists of the sale to third parties of the electricity (€51.2 million in 2024) that the Group does not use in the production process of its main activity, and which is included in Annexes 1 and 2 of the EU Taxonomy Regulation as an eligible activity with respect to the objectives of climate change mitigation and adaptation to climate change. The rest of the energy sales correspond to income from the sale of electricity transformed at the Zacapu facilities (Mexico), an activity that is not eligible according to the taxonomy.

Viscofan has not availed itself of the exemption from disclosure of information referred to in Article 18(1)(a) of Directive 2013/34/EU on the breakdown of business volume by category of activity, as well as by geographic markets, to the extent that those categories and markets differ significantly from each other, taking into account the way in which the sale of products and the provision of services is organised.

Therefore, the revenues obtained by the Viscofan Group can be grouped by nature into Traditional Business, New Business and Energy, which are significant for Viscofan based on the provisions of point AR 13 of ESRS 2 and account for 100% of revenue. Its breakdown is as follows:

| In thousands of euros | 2024 | % |

|---|---|---|

| Traditional Business | 996,611 | 82.8% |

| New Business | 147,326 | 12.2% |

| Other energy income | 60,057 | 5.0% |

| Revenue | 1,203,994 | 100.0% |

However, from a management information point of view, the activity is considered a mono-segment, being mainly the sale of casings as stated in Note 18 of the Consolidated Financial Statements according to IFRS 8.

At Viscofan, sustainability incidents, risks and opportunities are considered both in our operations and throughout the value chain. In particular, in the double materiality assessment detailed in section 1.1.4. Management of incidents, risks and opportunities, environmental aspects have been considered and evaluated, such as emissions, pollution, circular economy and dependence on natural resources, as well as social aspects, with greater relevance in the personnel of our operations and in the end consumer since our products are a part that facilitates the feeding of millions of people in all the same areas. The thematic ESRS sections describe the specific IROs identified, the policies established, resources allocated, parameters and goals.

Within the framework of the Sustainability Action Plan, there are no specific sustainability-related targets set in terms of significant product and service groups, customer categories, geographical areas or stakeholder relationships.

Traditional Business - Casings

In sausage production, food companies can use animal casings or casings made from natural primary materials. These are soft, cylindrical containers that give sausages and cured meats their distinctive shape and are of great importance to our customers in their quest for greater efficiency, increased production speed, reduced waste, and quality assurance.

The casings are characterised by their ease of use and appearance, which contrasts with the high technological component underlying the manufacturing process and which only a few companies worldwide have developed.

In particular, collagen casings provide specific characteristics and benefits for the meat industry compared to traditional sausage production methods using animal casings.

The advantages of collagen casings include their uniformity and consistency, which allows for more efficient, standardized production and better utilization of raw materials. They are also easier to handle and do not require prior preparation, unlike animal casings.

In addition, since food safety is a key aspect in food production, collagen casings are manufactured under highly controlled and standardized conditions, which reduces the possibility of contamination with pathogenic microorganisms, while also providing a longer and more stable shelf life. They do not require prior cleaning, eliminating the risk of cross-contamination that could occur during the cleaning process.

Finally, the production of collagen casings, and specifically at Viscofan's production plants, is subject to rigorous health and quality regulations. See details in the NEIS S4 Consumers and End Users section.

There are different types of casings depending on the main raw material used.

- Cellulose casings: The main raw material is cellulose, a linear polymer composed of glucose units found in the wall of cells in plants, wood and natural fibres, usually combined with other substances such as lignin, hemicelluloses, and other components. To produce casings, the cellulose chain must be broken to obtain a polymer with the appropriate length for its extrusion in the form of a casing and with very specific elastic properties. This process requires cellulose with a high level of purity, also called "premium cellulose" or "special cellulose" by our approved suppliers.

- Collagen casings: Collagen is a very common long fibrous protein with remarkable chemical and mechanical properties. In addition to its application for sausage casings, it includes uses in the fields of biomedicine, cosmetics and the food industry, as a basic material used in the broader gelatin industry. The corium, or inner part of the skin of cattle, is mainly used to produce collagen casings, since it is very rich in collagen.

- Fibrous casings: A combination of cellulose and abaca paper, the latter is obtained from a herbaceous plant called Musa textilis. Paper made from its fibres has a high mechanical and moisture resistance and is used at Viscofan to produce fibrous casings. Abaca fibre is also used by other industries to produce high quality paper and non-woven textiles for various uses such as tea bags, paper money and filters.

- Casings, film and plastic bags: obtained by treating different plastic polymers widely used in different industries. The most commonly used polymers are polyethylene, polypropylene and polyamides.

In addition, Viscofan also uses the following inputs for the production process:

- Chemicalsused as auxiliaries in the production of different types of casings, the most relevant are caustic soda and glycerine.

- Water: Viscofan's production plants require water collection for different phases of the process, such as the washing of casings, refrigeration, steam production and the moistening of said casings. At Viscofan's production plants, in 2024, 14% of the water captured evaporated, was incorporated into the product or was consumed, while the remaining 86% was taken to purification plants installed at Viscofan's production plants to be processed before being returned to freshwater surfaces or municipal processing plants.

- Energy: casing production is a continuous and energy-intensive process, mainly due to its drying phase. Based on the current state of technology, the most efficient form of energy generation for the production of casings is based on the combustion of natural gas. This is the main energy input used by Viscofan in its plants and it is supported, in turn, by electricity consumption.

To ensure the supply of key raw materials, Viscofan works with a series of certified suppliers and based on solid and long-lasting relationships. Additionally, within the procurement strategy, the search for supplier diversification is key, both by type of material and by geography. In this sense, one of the pillars of action of the R+D department is to carry out research aimed at expanding the range of suitable materials for the manufacture of casings and their performance, also taking into account sustainability criteria such as their biodegradable or recyclable nature.

The food industry and, more specifically, the cold meat production sector, increasingly demands more products with greater features, more sustainable and at highly competitive costs, in order to enable their large-scale manufacture. Responding to this demand involves a huge technological and development challenge that Viscofan has successfully met as the largest casing producer, being the only one in the industry to provide solutions in the main casing families.

Casings are an essential element in the production of food, allowing access to protein for millions of consumers. They are sold by Viscofan directly or through distributors to the meat industry for the production of sausages. Viscofan has the largest production presence in the industry and sells its products in more than 100 countries. They are transported mainly by truck or ship, depending on logistics needs.

Sausages are generally sold by the meat industry to supermarkets and restaurants, although, in the vast majority of the casings with which they have been produced are not perceived by the consumer, especially in the case of cellulosic and fibrous sausages, they are peeled by meat companies in most cases before being sold.

An increasingly conscious consumer when making purchasing decisions, which requires more transparency about the environmental and social impact of products, functional performance, the safety classification and traceability of production throughout the value chain.

Belonging to the food market carries with it a great responsibility: that of providing millions of people worldwide with access to basic nutrition. A population that is continuing to grow and whose expectations in terms of taste, preparation and consumer experience also continue to change and diversify, demanding a maximum food quality and safety guarantee.

| Category | Trend |

|---|---|

| Population growth | An average annual rate of 1%, with emerging areas driving this expansion. |

| Eating habits | Increased per capita demand for meat led by emerging areas thanks to the increased purchasing power of the middle classes, globalisation of eating habits and the growth of the population in cities. In developed areas, nutritional trends are evolving towards the search for chicken protein, greater convenience, and products with higher nutritional quality and food safety standards. |

| Greater sophistication of meat processors | Increased search for productivity, food safety and hygiene, and the development of new products drives the replacement of animal casings with artificial casings (mainly collagen), as well as the development of new products. |

In 2024, it is estimated that the casing market has grown by 3% in volumes once the inventory adjustment process seen in the previous year has been completed. The strong growth in collagen casings, driven by the market recovery, is noteworthy, together with the trend of replacing animal gut.

Thus, in 2024 the casings market has an estimated value of €5 billion. In order to meet stuffing requirements, a meat processor must choose from among the different market alternatives, either with animal gut (44% of the market) or artificial casings (56% of the market), which, in turn, can be produced with different materials, depending on the desired production and product characteristics, combining a better range of casings with production savings.

New Business

The know-how and experience acquired in diversification with the use of collagen as an ingredient in different applications not related to the world of casings, our continuous dialogue with the market allowing us to identify needs not always associated with casings, together with the experience we have gained in our own production processes, have given rise to product solutions framed within the New Business division.

With this division, Viscofan goes beyond the traditional casing market and enters a market with a potential of more than €5 billion in which Viscofan has a small size, but it is undoubtedly a great opportunity for its products and innovations that seek to provide solutions to trends in the areas of food and health that are becoming increasingly relevant.

The main growth catalysts identified are:

| Category | Trend |

|---|---|

| Population |

|

| Eating habits |

|

| Food industry |

|

| Health |

|

Diversification

Within the New Business division, Viscofan has a diversification-driven unit that actively pursues and develops growth opportunities and cutting-edge innovation in materials and new Business beyond casings.

These opportunities are explored and developed directly by internal teams and through partnership agreements with third parties that stand out in specific areas (technological, industrial, medical, etc.)

Food, health and sustainability activities are the main pillars of diversification activities.

Of these, Viscofan's ample knowledge in the processing, use and transformation of raw materials of a biopolymeric nature constitutes an investment opportunity and, hence, a growth opportunity for Viscofan. A good example are the new solutions based on the technological knowledge of collagen.

Collagen is the most abundant protein in the human and animal body, but at the same time it is a unique and versatile material, and therefore finds applications in various fields beneficial to people's health such as regenerative medicine, nutrition, health, life sciences, etc. Viscofan applies technologies and extraction methods to process bovine skin collagen for the development and production on an industrial scale of new collagen biomatrices in the medical, nutraceutical and dietary fields.

In 2024, Viscofan promoted the diversification of collagen-based products with the acquisition of a 60% stake in Brasfibra and Master Couros in Brazil, companies with their own collagen treatment technology that is allowing Viscofan to strengthen its knowledge and product portfolio in collagen hydrolysates and expand its use as a food ingredient or solutions for the pet food market.

In addition, Viscofan explores new business avenues by taking minority stakes in several disruptive start-ups, providing financing, and in some cases knowledge, resources and access to markets to facilitate their growth. The investee companies are (ODS Protein, Feltwood, MOA Biotech, Insekt Label Biotech, Cocoon Bioscience and Inmedical Therapeutics).

Viscofan also participates in alliances in which it shares knowledge for the development of innovative solutions in different fields. In this regard, the following stand out: The TriAnkle project, a consortium of companies led by Viscofan and funded by the EU to manufacture personalised 3D implants based on collagen and gelatin for the regeneration of injured tendons and cartilage; the European consortium Accelerating Research and Innovation for Advanced Therapies (ARDAT) for the development of advanced therapy medicines; and the European consortium projects "Brave" on cardiac regeneration and "Unloc" on 3D solutions for the field of "Organ on a Chip".

Finally, with the "Protection" and "Probonewfood" projects that seek to research new sources of protein and their impact on the immune system, and which are funded by the CDTI in Spain.

Our competitive advantages

Viscofan's progress is understood from achieving sustainable competitive advantages, which are the result of the work and commitment of an exceptional team that has been offering the best of each one of them for nearly 50 years, to turn Viscofan into the leading company in the casing sector and to expand its frontiers towards new Business in the fields of food and wellness.

People and values

People are the differential value on which the future of Viscofan is being built. Our team is made up of 5,163 people, of which 2,788 are in the EMEA region, 1,289 in North America, 602 in South America and 484 in Asia Pacific.

A team distributed throughout the world but based on shared values:

- We are resolute: we strive for excellence in quality, we are customer and results oriented, we are committed to our work and we carry it out in an agile manner.

- We work as a team: we perform our work with passion, we value know-how, agility and excellence. We like to work as a team with a common purpose.

- We are pioneers: we look for new ways of doing things, taking the risk of going further, diversifying, innovating and contributing to a better future.

- We enjoy our work: we are excited about life, we are eager to do things, make decisions and seize opportunities. We value responsibility and commitment to work.

In parallel, these values are based on irrevocable ethical principles (integrity, loyalty, respect and human rights).

The Viscofan Group understands that the creation of long-term sustainable value for all stakeholders can only be achieved through ethical behaviour that favours the development of a culture of best practice in social responsibility within the Group and by contributing to improving people's well-being through the economic, environmental and social development of the communities in which the Viscofan Group is present.

R&D and Innovation. Technology and know-how

Viscofan's position in the constantly-evolving, highly competitive world market is sustained by its constant cutting-edge efforts in research, development and innovation (R&D&i), both in technology and products. Only this philosophy enables the company to advance the leadership of innovations in the casing industry worldwide and to drive and develop new business, thus benefiting the various stakeholders.

This activity is possible thanks to an innovation network and culture that extends to the whole organisation, and the corporate research and development centre in Spain coordinates, directs and supports the specific research and development activities and tasks conducted at each production plant and coordinates the multidisciplinary work teams. The corporate centre seeks to share the best practices, technological knowledge and the ideas between the different production centres.

Constant innovation required by our globalised world must be taken into account. Our products must be compatible and adapt to the food habits and uses of millions of world consumers, their preferences and evolution over time. Viscofan accompanies its growth as a company with the development of its innovative capacity to access, assimilate and improve the best technologies available in the market, as well as to develop its own technologies that provide competitive advantages, while promoting continuous improvement, seeking greater efficiency and greater sustainability in the improvement of processes and products.

In this regard, Viscofan adapts a proactive approach in the search for sustainable solutions at technology and product level, boosting relevant aspects, such as the circular economy, the search for energy efficiency, the reduction of GHG emissions, pollutants and the lesser need for water.

Progress in the field of digitalisation represents a new innovation opportunity that Viscofan wants to take advantage of to lead the industry's digital transformation. In collaboration with third parties, Viscofan's Digital Transformation team wishes to apply the solutions offered by new IT technologies to our operations. We are seeking to improve the quality of our products, to obtain the best information possible to improve our production process and to perform predictive maintenance, etc., through solutions based on artificial vision, the development of technological solutions with the digitalisation of the movement of materials within the facilities, and the development and implementation of a smart 4.0 industry management system.

Innovation is an on-going process with strategic product and technological development projects in all casing families (cellulose, collagen, fibrous, plastic and vegetable), and in its final product applications, also including other diversification products. Our innovation boosts the innovation of the food sector, enabling applications to be developed aimed at providing Viscofan with the range of products required to reinforce its presence on the global market.

Action projects

With this, the main current projects are mainly oriented towards the following areas:

- The development of new products according to the target markets as defined in the expansion plan, and those required by our customers, and also new generation executions, designed and oriented towards offering tubular alternatives with differential performance and features.

- The development of films and casings that are able to confer functionalities to the product they contain, gaining in efficiency and preventing food waste.

- The development of production alternatives and technological solutions that involve a radical leap, through modernisation, streamlining and simplification, allow an increase in added value and efficiency levels and significantly reduced production costs for meat casings, thus improving the competitiveness of our products and processes.

- A boost in the search for technological solutions that allow us to improve the sustainability of our operations in energy efficiency and water consumption, efficiency in the use of raw materials and waste and pollutant reduction and improvements in safety.

- Research aimed at extending the range of adequate materials to manufacture casings and their features, while also taking into account sustainability criteria such as their biodegradability or recyclability.

- Technological support for improving existing products and processes, and for the Company’s international expansion, all this adhering to Viscofan’s technological and quality standards and current regulations, as well as the optimisation of production costs.

- Digitalisation: Within the Digital Transformation Department, Viscofan has an Advanced Data Analytics area, whose actions during the year included the implementation and development of a demand prediction model in collaboration with a third party.

Our assets. Wide product offer

Viscofan is the only company in the casing industry with the main technologies available, and offers its customers a wide portfolio of casings that allows them to choose the one that best suits their needs in a context of globalisation in food habits and the need to adapt to changing consumer demands where the focus on health, convenience, experience, variety and sustainability awareness are more relevant.

Our casings facilitate access to basic food for a growing world population, especially in emerging areas whose consumption habits increasingly demand more protein, whether of animal or vegetable origin.

Our broad casing product portfolio, the largest in the industry, allows the customer to choose the casing that best suits their needs, while with the new Beyond25 vision and Strategic Plan we expand frontiers with innovative New Business solutions that go beyond traditional casings.

During the year, the most significant changes in the product portfolio were the incorporation of Brasfibra's collagen products in collagen hydrolysates, as an ingredient in food and pet food.

Our product categories are as follows:

Traditional Business

Cellulose casings

They are made using natural cellulose as a raw material. They are primarily used for the production of industrially cooked sausages.

“Casing that provides competitiveness in an inflationary environment, and sustainability due to its plant-based and biodegradable origin.”

Collagen casings

They are made using collagen as a raw material, ideal for fresh or precooked, or raw/cured sausages.

“An attractive alternative to animal casings, supporting customers with their automation and cost-saving challenges.”

Fibrous casings

Made with a blend of cellulose and abaca paper, a plant-based paper that gives the casing high strength and consistency for the production of large-caliber sausages.

“The best solution for today's industrial processes, which increasingly demand speed, productivity, and efficiency.”

New Business

Plastics

Casings, films, and bags obtained through the treatment of plastic polymers, also promoting the use of renewable and bio-based raw materials. A wide variety of types is available, allowing us to offer the most suitable product for each type of application.

“Focus of growth on sustainability and added value.”

Vegetable casings

Plant-based and specially developed for vegetarian and vegan recipes. Suitable for fresh and cooked applications, with excellent frying results and a tender bite.

“Viscofan has been a pioneer in developing a tubular product.”

Transfer of spices

Functional spice transfer solution applicable to a wide range of foods such as fresh produce, processed meats, cheeses, and ready-to-eat products.

“New generation of solutions to help customers in their search for new products.”

Edible films

A transparent, edible, and soluble film made from plant-based polysaccharides that serves as a carrier for a wide variety of herbs, spices, sauces, and marinades.

“Disruptive innovation to reach more markets.”

Hydrolyzed, satiating and other collagen-based products

Collagen plays an important role in our bodies. It supports tendons, skin, and cartilage, thus supporting the integrity, firmness, and elasticity of the musculoskeletal system, soft tissues, and skin.

"A premium product leveraged on Viscofan's experience with this raw material and reinforced in 2024 with the acquisition of Brasfibra."

Nutra-pharma-bio

Processed bovine skin collagen products for the development and industrial-scale production of novel medical and research-grade collagen biomatrices.

“Leveraging our collagen know-how in the medical field.”

For more information on Viscofan's products, please consult the Products and Markets section of the corporate website.

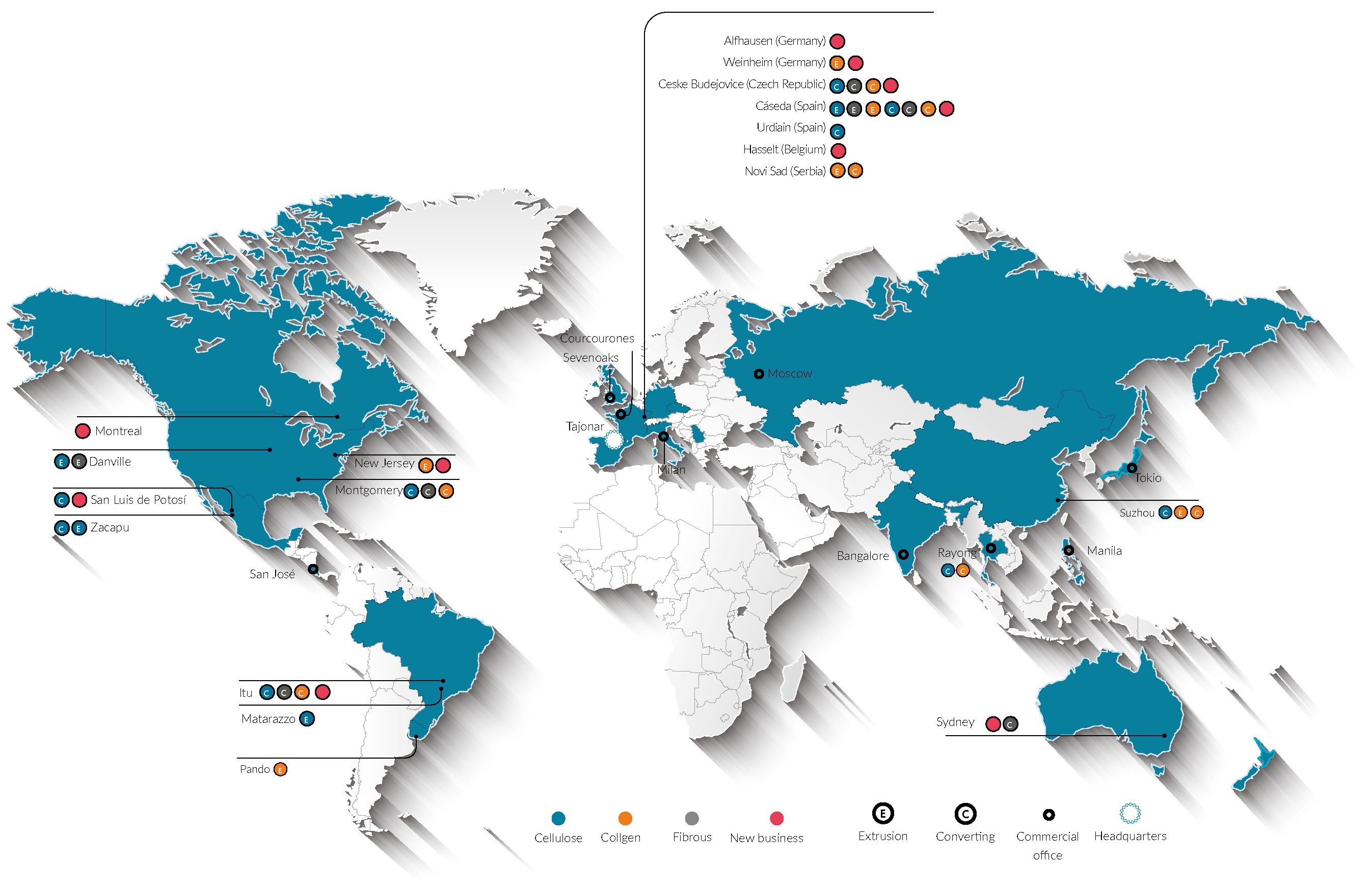

Our assets. Geographical presence

The casing market is global. Our customers are located in more than 100 countries around the world, so providing a quick response adapted to their needs is often a differential element of their purchase decision. To improve this response capacity we have the largest production and sales network in the market, with a presence in 21 countries and 24 production plants.

Geographical expansion is a constant at the Viscofan Group. In 2024, the construction and commissioning of a converting plant for collagen and cellulosic casings in Thailand was completed with the aim of improving service in Southeast Asia, one of the casing markets with the best growth prospects.

Also in 2024, Viscofan acquired the companies Brasfibra and Master Couros, which have implemented production of collagen-based products in Brazil.

In addition, between 2021 and 2023, the company Viscofan Japan GK was set up with the aim of having its own commercial presence in Japan, one of the world's main casing markets and the opening of representative offices in Italy and the Philippines with the aim of improving service in these significant markets and enhancing our knowledge of them.

Generated and distributed value

ESRS 2 SBM-1 paragraph 42.b)

The results in terms of benefits of Viscofan's products and services and activity for the main stakeholders are described below.

Customers and end consumer

Our casings facilitate access to basic food to the world's population, achieve greater efficiency in production, following strict quality and food safety controls, and clarity in labelling. Listening to the customer is key to meeting these demands in order to offer them the most suitable product and to promote them in order to achieve a more sustainable industry.

At the same time, we can also help improve the well-being of human beings through nutrition and our knowledge, mainly through products that derive from the know-how we have achieved by producing and marketing collagen-based products for food and health uses.

Raw material and service suppliers

Viscofan makes a global commitment to its suppliers and establishes relationships with them based on respect and trust, and on the quality of products and services. On this basis, it works closely with its suppliers to understand their specific needs and challenges. This collaboration allows for developing tailor-made solutions that benefit both parties and create long-lasting and successful business relationships.

Likewise, Viscofan, based on its commercial relationship and trust with suppliers, seeks in all the companies of the Group the payment of invoices in a timely manner, regardless of their size and category.

Employees

Ensure decent working conditions for all company employees, with non-discriminative hiring. Likewise Viscofan maintains its commitment to create ongoing employment.

We back the promotion and professional development of our teams, especially among young people. We inform employees of the opportunities and processes that arise at the company so that they can opt for new goals and challenges.

Guaranteeing freedom of association and collective bargaining.

Creating a stable working environment, supporting full-time permanent contracts, in a climate of respect and non-discrimination. 93% of our workforce have permanent contracts.

Encouraging youth employment through recruitment and internship programmes.

Having occupational health and safety management systems at all the company's factories.

Shareholders

Throughout the different strategic plans, the Viscofan Group has built a sound and flexible business model. This characteristic entails the creation of cash flows that allow investment projects to be carried out in order to improve value creation, which is shared with shareholders in cash and at the same time maintaining a sound balance sheet structure. Accordingly, against the results of the 2023 financial year, Viscofan distributed to shareholders a dividend of €3.01 per share, which includes an extraordinary dividend per share of €1.00. In addition, against the results of the 2024 financial year, the Board of Directors has proposed a total dividend of €3.10 per share, includes an extraordinary dividend per share of €1.00.

Company

In its Sustainability policy, the Viscofan Group has a firm commitment to Human Rights, undertaking to carry out its activities in a responsible manner and to generate positive impacts on the communities in which it operates. In this regard, in 2023, Viscofan implemented different social initiatives through the help of different bodies and institutions in the communities in which it is present, while collaborating with institutions or research centres.

Viscofan is aware of the social impact its activity generates: from direct or indirect employment generated by its implementations, to the financial benefit it obtains from its activity in each of the different companies in which it operates for which it contributes through taxes. In 2024, accrued income tax amounted to €49.1 million as a result of the Group's business activities in different countries.

Vision and strategic goals

In the current strategic plan Beyond25 Viscofan aims to accelerate growth compared to previous strategic plans with transformation projects that allow us to strengthen leadership in the Traditional Business and gain size in the New Business, doing so in a profitable way and while we move steadily towards the achievement of the Sustainability Commitments set for 2030.

The targets set are:

- Our financial targets for the 2025 period are as follows:

- Revenue: Grow between 5% and 8% compared to fiscal year 2024.

- EBITDA: Grow between 8% and 12%.

- Net profit attributable to the parent company: Growth between 6% and 10%.

- Investment of 75 million euros.

- Our sustainability commitments are as follows:

- Climate change: Net Zero Plan 2050 approved in 2024 by the Board of Directors with an intermediate target of absolute reduction of GHG emissions in the range of 45% to 50% by 2030 compared to 2018.

- Circular economy: 30% reduction in tonnes of waste disposed/million metres extruded in 2030 compared to 2018.

- Water: 10% reduction in water abstraction in m3/million extruded metres in 2030 compared to 2018.

- Accident rate: 50% reduction in the severity rate at work compared to 2018.

- Diversity: 30% of women in executive posts by 2030.

- Supply chain: verification of 100% of suppliers of the main raw materials committed to the code of ethics in 2030.

Interests and views of stakeholders

ESRS 2 SBM-2

The Viscofan Group understands sustainability as the ability to create value among its various stakeholders in the short, medium and long term without compromising the well-being of future generations. In this sense, the challenges of Viscofan's global sustainability and its value chain require a collaborative approach in order to design common solutions.

Participating in a dialogue means respecting all stakeholders, contributing to Viscofan's value proposition and taking the opportunity to learn from their points of view. It is key to promote transparency in information and communication.

To achieve this commitment, appropriate communication channels have been identified and established to ensure an open dialogue and to be aware of their needs and expectations, allowing the identification and analysis of the most relevant aspects of value creation that inspire the Viscofan Group's success strategy.

In this regard, in 2024 Viscofan has developed a double impact materiality assessment taking into account the opinions of stakeholders and which in turn translates into the identification of materially important incidents, risks and opportunities. This assessment was coordinated by the Investor Relations, Communication and Sustainability Department and in which the Executive Sustainability Committee has also participated and the results have been reported to the Board's Audit Committee within the framework of the preliminary work to adapt to the regulations governing this report.

In addition, in the year Viscofan has developed and the Board of Directors approved a Net Zero Greenhouse Gas Emissions Plan within its commitment to SDG 13 Climate Action and to respond to the interests of society in general, shareholders and agents in the value chain. This plan will serve as a catalyst to minimise Viscofan's impact on Climate Change, the risks associated with it and, at the same time, represent an opportunity to improve Viscofan's reputation and an additional competitive advantage over competitors that do not have a similar strategy. See detailed description of the plan in ESRS E1 – Climate Change.

Details of stakeholders and communication channels:

| Stakeholder | Specific communication channels | Sustainability issues | Value proposal | ||

|---|---|---|---|---|---|

| Shareholders | General Shareholders' Meeting, roadshows, conferences, telephone contact, electronic communication platforms, and via email, corporate website, shareholder services branch, etc. | Financial and reputational impact of issues | Sustainable economic growth | ||

| Employees | Intranet, global opinion poll, meetings and presentations, training sessions, direct relationship with managers, internal magazine, whistleblowing channel, bulletin boards and information screens | Accident rate at work Respect for human rights |

Developing talent and skills by promoting a safe and diverse work environment | ||

| Customers | Customer satisfaction surveys, seminars and events organised by Viscofan, telephone and email technical assistance and continuous service, end-to-end claims and complaints system, active presence in trade fairs, visits to and from customers, local presence through agents and distributors, access to an extranet for customers accessible at the Viscofan Group's corporate website. | Food security crisis | Preferred option in line with its needs to improve process efficiency and sustainability.

With these new businesses, Viscofan offers products that improve people's health and well-being, with end-use applications ranging from food and nutrition to biomedical and cosmetic uses. |

||

| Suppliers | Direct contact, collaboration agreements, training, assessments and audits | They face environmental and social sustainability challenges that are similar to those of Viscofan. | Alliance and respect in the search for the best solutions in our activity. | ||

| Company |

Contact with the local community, civil society actors, partnership agreements, sponsorships, etc.

Contact with governmental institutions, associations Collaboration with research centres and institutes in different countries |

Greenhouse gas emissions

Air and water surface pollution Impact on the environment due to the increase in waste disposed of |

Sustainable economic growth, information transparency, territorial integration and community development |

Alliances

One form of collaboration with stakeholders is to establish alliances with different entities. Viscofan has a long history of collaborating with institutions or research centres in different countries and it is part of and promotes various associations and groups that, among other things, are seeking to find ways for industry to collaborate in increasing its contribution to the material aspects of sustainability. These institutions include:

- Comité International de la Peliculle Cellulosique (CIPCEL). Based in Brussels, CIPCEL comprises the leading producers of regenerated cellulose film products.

- Collagen Casing Trade Association (CCTA). An association of leading producers of collagen casings worldwide that provides a forum for its members to discuss the development of legislation and actively promote the use of collagen casings.

- Centro Español de Plásticos (CEP). This is the Spanish association of entities relating to the manufacture and processing of plastics.

- European Association Plastic Converters (EUPC). European association that groups together national plastic converter companies and associations.

- Working group of the Gelatine and Collagen Lebensmittelvberband (Germany). An organisation of German gelatin and collagen manufacturers.

- AINIA. Food technological centre based in Spain that supports the R&D tasks of its partners, especially in the areas of quality, food safety, sustainability, environment, design and industrial production.

- ANICE. The Spanish National Association of the Meat Sector is the biggest meat association in Spain to provide advice, represent and defend the sector's interests.

- National Centre for Technology and Food Safety (CNTA), the purpose of which is to provide advanced technological services to improve competitiveness in the food sector through quality and innovation and under the principle of food safety.

- CEO for Alliance for Diversity. An alliance whose mission is to uniting companies around a common and innovative vision of diversity, equity and inclusion, and accelerating the development of strategies that contribute to business excellence, the competitiveness of talent in Spain and the reduction of inequality and exclusion in Spanish society.

- AIMPLAS. The Plastics Technology Centre offers integral solutions to companies within the plastics sector through the technical implementation of R&D&i projects.

- NAITEC. Multidisciplinary Technology Centre for the Industry.

- National Centre for Renewable Energy (CENER). A prestigious technology centre recognised for its activity, both in Spain and in other countries, which carries out applied research in renewable energies and provides technological support to energy companies and institutions in five areas: wind, solar thermal, solar photovoltaic and biomass energy, energy transition in cities, grid integration, and electrical and hydrogen storage.

- Project "Development of Advanced Technologies and asset management tools for the Efficient Production of Green Hydrogen for use in the decarbonisation of Industrial Processes".

- European Business and Innovation Centre of Navarra (CEIN). A centre committed to entrepreneurship, innovation, growth and business collaboration in Navarra.

- IndesIA. An association promoting the use of artificial intelligence and big data to make Spanish industry a global benchmark.

- The Consejo España – EE. UU Foundation. A civil society initiative that promotes dialogue and aims to strengthen the ties between Spain and the United States to heighten mutual understanding.

Viscofan also collaborates with different universities and research centres:

- University of Navarre (Spain)

- Public University of Navarre (Spain)

- CIDAUT Foundation for Research and Development in Transport and Energy (Valladolid, Spain)

- MORE Institute Research (Germany)

- Hochschule Manheim Fraunhofer Institute (Germany)

- Tübingen University (Germany)

- Sao Paulo University (Brazil)

- Suzhou University (China)

- Technology University of Uruguay (UTEC)

- University of the Basque Country (Spain)

Moreover, Viscofan is importantly supported by the different administrations of the countries where it develops R&D activities, for example: the Centre for Technical Industrial Development (CDTI) and the Ministry of Economy and Competitiveness (MINECO) in Spain, the Federal Ministry of Education Research in Germany, the National Science and Technology Council (CONACYT) in Mexico, the Institute for Technological Research (IPT) in Brazil and the Federal, Illinois and New Jersey R&D Credit of the US Federal Government, the State of Illinois and the State of New Jersey